What is Precision engineering?

- Prasad Urankar

- Apr 29, 2025

- 1 min read

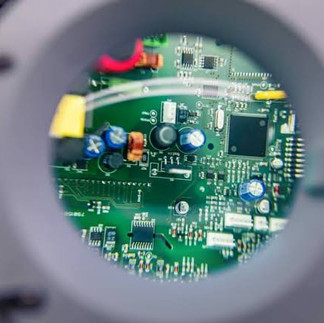

Precision engineering is a specialized field that focuses on designing, manufacturing, and measuring components and machines with extremely high accuracy and repeatability. It involves using advanced techniques and technologies to achieve tight tolerances and dimensional control in the manufacturing process.

Here's a more detailed look:

Key Aspects of Precision Engineering:

High Accuracy:

Precision engineering aims for exceptional accuracy, often with tolerances measured in microns (one-millionth of a meter) or even nanometers.

Repeatability:

Components and machines produced through precision engineering are designed to be manufactured consistently and repeatedly to exact specifications.

Advanced Technologies:

It utilizes advanced manufacturing techniques like CNC machining, laser cutting, and micro-stamping to achieve high precision.

Metrology:

Precise measurements are crucial, and advanced metrology tools like Coordinate Measuring Machines (CMMs) are used to ensure accuracy.

Wide Applications:

Precision engineering is used in a wide range of industries, including aerospace, medical devices, electronics, and semiconductor manufacturing.

Examples of Precision Engineering:

Micro-parts:

Precision engineering is used to create tiny components for microelectronics and medical devices.

CNC Machining:

Computer Numerical Control (CNC) machining is a common precision engineering technique used to manufacture parts with intricate details and tight tolerances.

Optical instruments:

Precision engineering is essential for the design and manufacture of optical instruments like telescopes and microscopes.

Aerospace components:

Precision engineering ensures the accuracy and reliability of critical components in aircraft and spacecraft.

In essence, precision engineering is about creating products and machines where even the smallest variations can have significant consequences, demanding a high level of accuracy and control throughout the entire manufacturing process.

Comments